New 3SR squeegee increases aperture filling, reduces paste sticking, and minimises stencil wear

Yamaha Robotics SMT Section has revealed an innovative squeegee design for surface-mount screen printing that raises process performance and extends stencil life.

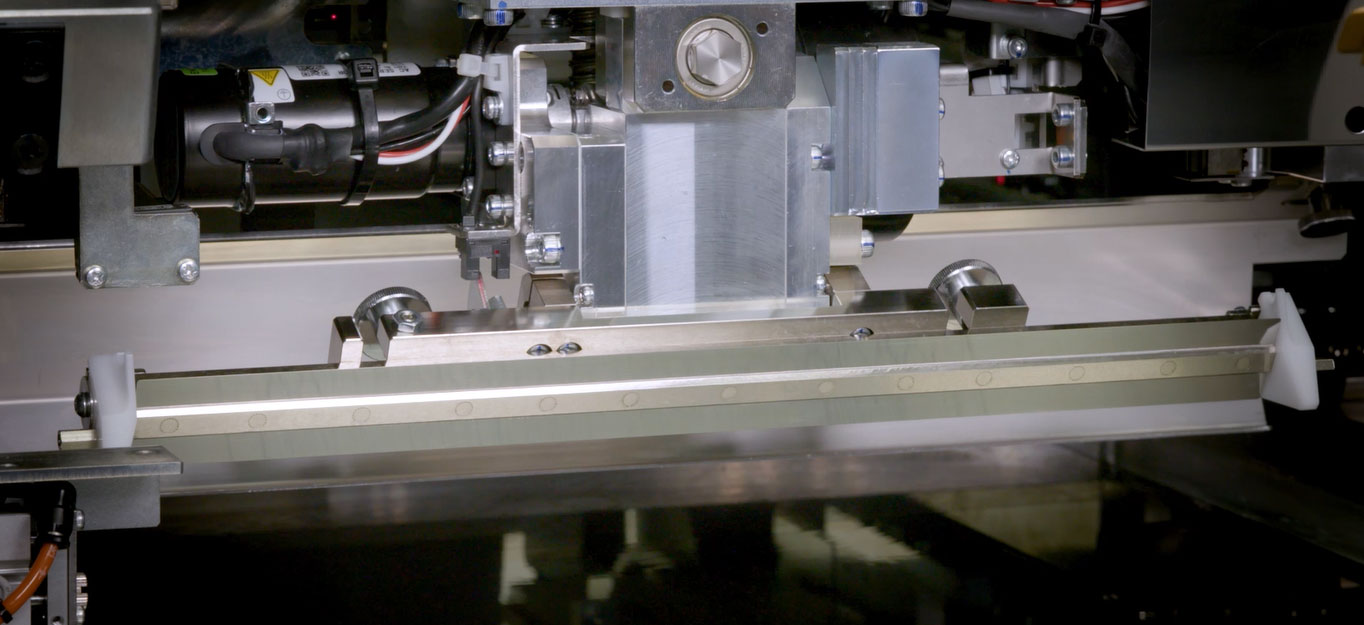

The new 3SR squeegee introduces an enhanced blade profile that improves solder-paste rolling increases aperture filling by up to 5% and ensures consistent performance as the solder-paste roll diminishes. Supplied as standard with Yamaha’s latest YRP screen printers, the 3SR can also be fitted as a direct upgrade for YSP machines.

The Yamaha 3SR squeegee increases filling power while protecting the stencil

The Yamaha 3SR squeegee increases filling power while protecting the stencil

Yamaha recorded up to 5% greater filling in tests with stencils containing apertures from 0.3mm to 5mm. The tests showed increased filling for all aperture sizes, and with a 25% smaller paste roll than typical practice. The smaller roll size demonstrates reduced dependence on solder-paste mass, permitting increased process stability and reduced consumption of materials.

In addition, enhanced material properties of the 3SR squeegee ensure longer stencil life thereby sustaining process performance and reducing stencil replacement costs. Lower friction also prevents solder paste from sticking to the blade, helping to reduce stoppage time for cleaning and to minimise discarded paste.

“The new 3SR squeegee achieves a measurable increase in aperture filling with reduced dependence on paste-roll size, ensuring greater process stability,” commented Kamil Stasiak, Product Marketing Manager EMEA SMT Section. “It’s a valuable step forward for screen printing that can increase the pass rate at solder-paste inspection and AOI, ultimately driving up end-of-line yield.”

The 3SR squeegee is avalable immediately and can be fitted without modification to Yamaha YRP and YSP screen printers in the field. For more information, please visit the website at www.yamaha-motor-robotics.eu.

About Yamaha Robotics SMT Section

Yamaha Surface Mount Technology (SMT) Section, a subdivision of Yamaha Motor Robotics Business Unit in Yamaha Motor Corporation, produces a complete selection of equipment for high-speed inline electronic assembly. This 1 STOP SMART SOLUTION includes solder paste printers, component mounters, 3D solder paste inspection machines, 3D PCB inspection machines, flip-chip hybrid placers, dispensers, intelligent component storage, and management software.

Bringing the Yamaha way to electronics manufacturing, these systems prioritize intuitive operator interaction, efficient coordination between all inline processes, and modularity enabling users to meet the latest manufacturing demands. Group competencies in servo-motor control and image recognition for vision (camera) systems ensure extreme accuracy with high speed.

The current product line includes the latest YR equipment generation, with advanced automated features for programming, setup, and changeovers, and new YSUP management software with state-of-the-art graphics and built-in data analytics.

Combining design and engineering, manufacture, sales, and service competencies, Yamaha SMT Section ensures operational efficiency and easy access to support for customers and partners. With regional offices in Japan, China, Southeast Asia, Europe and North America, the company provides truly global presence.